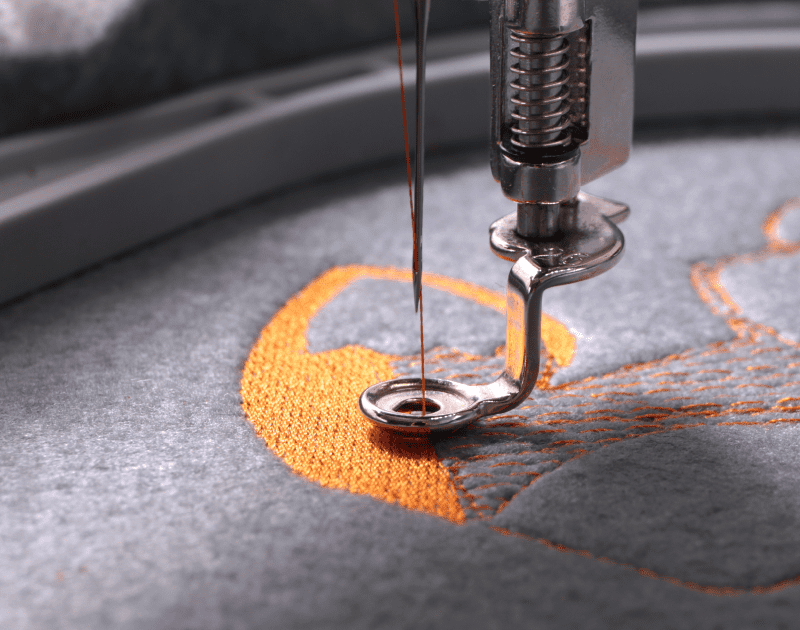

Embroidery is one of the single most popular techniques for applying a company name or logo onto various different workwear garments. In case you need a quick refresher, embroidery is the process of stitching a design directly onto a piece of clothing, creating high-quality, texturised and reliably hard-wearing results.

Embroidered personalised workwear is more than capable of enduring the relatively frequent and intensive washing that’s typical of most commercial garments, so it’s probably easy to see why it’s such a firm favourite of business owners, who often use it to establish or reinforce a strong shared identity for their brand.

Here at City Workwear, we don’t outsource any of our embroidery services, preferring instead to rely on the skills of our in-house team and the state-of-the-art machinery we have at our disposal.

Advantages Of Embroidering Workwear

High Quality

High QualityDistinctive, tactile designs and strong, vibrant colours help your company stand out from the crowd.

Professional Finish

Professional FinishExceptional quality that sends out the perfect first impression for your business, club or brand.

Long Lasting

Long LastingSophisticated manufacturing techniques create beautifully stitched designs that won’t fade over time.

Highly Durable

Highly DurableEmbroidered designs reliably can withstand frequent washing, harsh weather conditions and intensive work environments.

Key advantages of workwear embroidery (in detail):

Embroidery is known for providing an especially prestigious, professional look, thanks to the more solid feel of the finish compared to that of print. That alone makes it particularly valuable to businesses and clubs, whose staff will be wearing their polo shirts and other embroidered workwear in front of customers on a daily basis.

It combines this with key advantage with several more practical benefits too, most notably its durability. Because the design is physically woven into the garment, it’s exceptionally long lasting and therefore won’t fade in the wash, while standing up well to inclement weather like heavy rain, and other more gruelling elements of certain work environments. All of this means that the design will be around for as long as the garment itself. Partially because of this, it’s also frequently recommended for headwear, such as caps.

The flexibility of embroidery for workwear is another big draw. Certain types of customisation techniques are better suited to some types of garments rather than others, whereas embroidery can work with almost any kind of fabric. That makes embroidered workwear a highly accessible, reliable and effective option for almost any organisation, business or brand.

What garments can be embroidered?

Embroidery works with almost any clothing - it’s particularly useful for heavier garments, such as those designed for heavy use in intensive environments, including polo shirts, hi-viz jackets, hoodies, sweatshirts, business shirts or blouses, aprons or tabards, jackets, and headwear like hats and caps.

The hardwearing finish, combined with the tougher nature of these garments, means that embroidered workwear stands up well to conditions in even the most challenging environments, and will not fade with frequent laundering. That makes it useful not just for commercial workwear and company uniforms, but also for sports teams and similarly physically active organisations.

Coats and Jackets

Keep off grim weather with personalised coats, jackets and workwear.

Explore Range

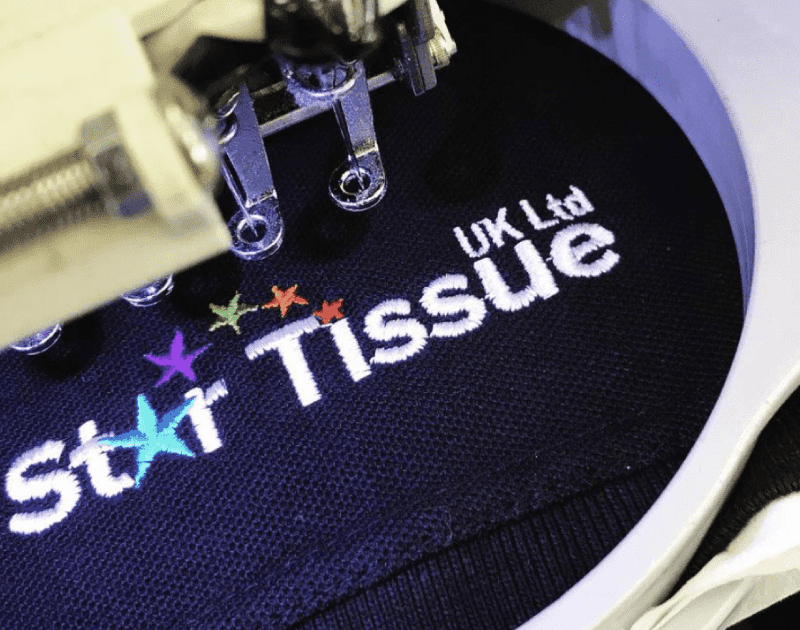

Workwear Embroidery Process

For the first step of the process, all we need from you is a high-resolution image of your artwork, rendered at an appropriate size. (This ensures that it will show up clearly on your finished embroidered workwear.)

When you send us your artwork, we’ll use the latest software to digitise it into a stitch format, ready for our embroidery machines. This gives us a file called a jacquard, which is designed to give an accurate indication of exactly what your garments will look like. The jacquard essentially acts a digital template for our specialised embroidery machines, which they’ll use to stitch your artwork onto your garments.

Each jacquard is stored on the machine itself, so it can be used and re-used as many times as necessary. (Contrary to popular belief, the amount of time it takes for the machine to finish each design is strongly dependent on the number of stitches in it, rather than the number of colours.)

So, as soon as your design’s been digitised, we’ll then send you a final PDF version, so that you can give your final approval before we go ahead.

As soon as the last instructions (such as the colour of the threads) have been submitted, the embroidery process itself begins. This involves a metal frame being placed onto the garment, while a backing fabric is applied to the logo area. This bit is important because it ensures that the garment is secure while the logo’s being stitched onto it. This can sometimes leave a temporary mark on the garment, but it’s easily removed by rubbing it off or giving it a quick wash.

Once the garments have been stitched, we just have to make a few final arrangements, and then we can ship your embroidered workwear to you. Simple and straightforward - just how we like to do things here at City Workwear.