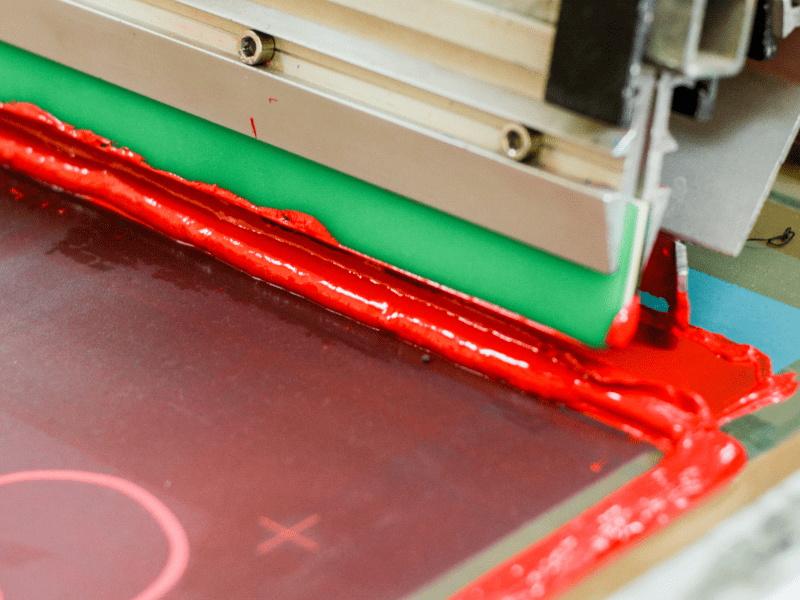

Screen printing essentially involves applying multi-coloured inks to your garment through the use of mesh screens. This form of printing is one of the oldest and most traditional forms, and it’s a cost-effective option for bulk purchases or workwear or large-scale product runs of 20 garments or more, such as mass produced retail products or promotional clothing. It tends to be best suited for bright and vibrant colours, as it conveys these better.

When you send your logo through to us, one of the first things we’ll do is separate it out into different colours. Each layer of colour will be applied individually using a different screen. Between each screen, we’ll use a heat lamp to ensure that the colours are setting properly. Once all of them have been applied, we’ll put the garment through a drying process to ensure that the design is permanent.

Advantages Of Screen Printing Workwear

-

Eye Catching Colours

Eye Catching ColoursDistinctive designs and exceptionally strong, vibrant colours help you stand out from the crowd.

-

Professional Finish

Professional FinishOutstanding quality that sends out the perfect first impression for your business, club or brand.

-

Detailed and Intricate Designs

Detailed and Intricate DesignsLayered designs can convey photographs or hand-drawn illustrations down to the last detail.

-

Economical In Large Batches

Economical In Large BatchesScreen printing is an excellent choice for large product runs, of at least 20 garments or more.

Key advantages of workwear screen printing (in detail):

Printing tends to be better at conveying larger designs or brighter colours, which can be great for catching passing glances and drawing more attention to a particular product, service or cause - making it a popular choice for advertising or promotional events. It’s also perfect for conveying far more intricate designs than embroidery, such as hand-drawn illustrations or photographs.

The process involves specially-formulated heavy-duty inks that are cured in a dryer, creating a physical bond between the ink and the garment itself, so you can rely on it not to fade over time. Screen printing is notably versatile, and can be used to create different kinds of prints, including metallics, 3D prints, puff prints, and gradient prints - just to name a few!

Setting up the machine accounts for the main cost and time involved in screen printing. As soon as it’s ready, the actual process of printing onto the garments can be done relatively quickly. This is one of the key reasons why it’s such a great choice for large product runs of 20 products or more. Anything less than that, and the resource involved in setting up the machine means that smaller volumes become increasingly less economical.

What Garments Can Be Screen Printed?

Screen printing is useful for a wide variety of garments, from t-shirts to hoodies, and it’s particularly well-suited for lighter garments such as T-shirts, or those used for advertising or promotional uses, such as one-off promotional or charity events. For these garments, printing is the best choice as it doesn’t have too much of an effect on the feel or the wearability of the garment, and won’t ‘pucker’ the material.

-

-

-

Coats and Jackets

Keep off grim weather with personalised coats, jackets and workwear.

Explore Range -