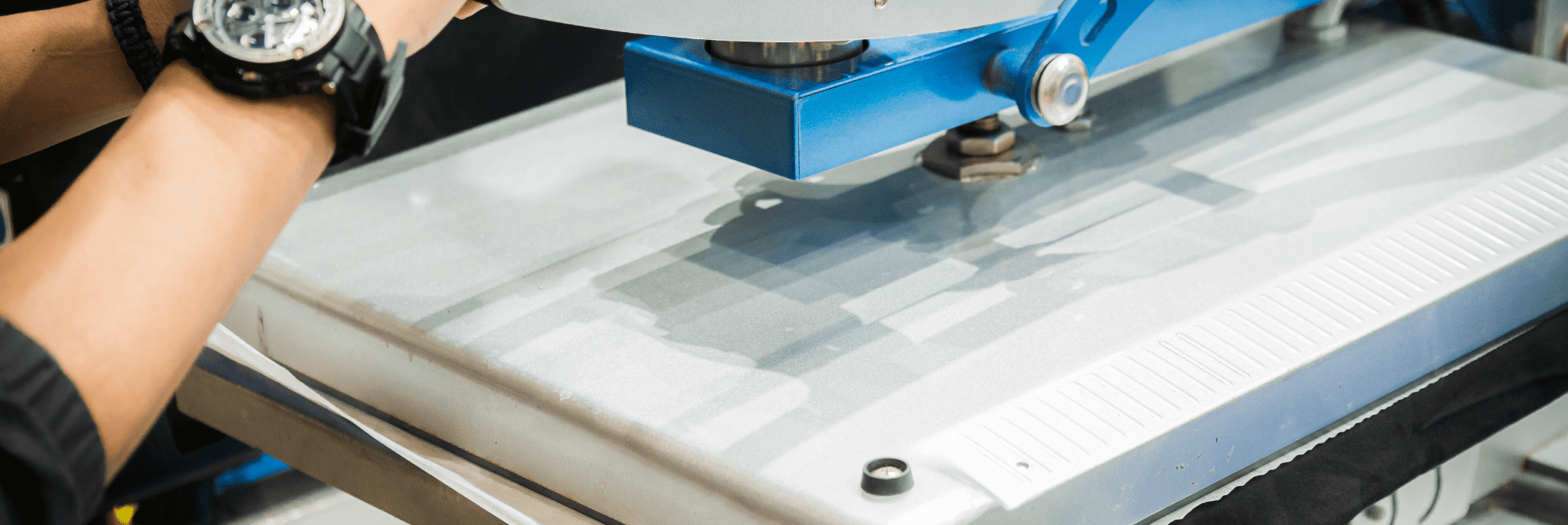

Transfer printing is a catch-all term which encompasses a small number of specific techniques, each of which rely on heat to transfer an image from surface to surface. Heat transfer printing involves first printing your design onto a specially-made transfer sheet, which is then laid onto your garment and pressed into it at high temperatures. The transfer sheet is then carefully removed to leave a perfect image of the design behind. Vinyl transfer printing works in much the same way - essentially, a sheet of vinyl is cut into the shape of your logo, and then we use a heat press to heat-seal it into the fibres of your garment.

Transfer printing is a particularly good choice if you need a relatively small number of garments, and it’s an excellent choice for printing detailed, vibrant full-colour designs. Vinyl printing offers a smaller selection of colours, so it’s best suited for single-colour individual names, numbers or logos.

In terms of material, transfer printing can be easily applied to almost any type of material, including fleece or wool. We often recommend it for personalising high-vis jackets, or small runs of T-shirts. In short, it’s a versatile, cost-effective and high-quality method of printing for a huge range of garments or accessories.

Advantages of Transfer Printing

-

Detailed, Full-Colour Designs

Detailed, Full-Colour DesignsHeat transfer printing can produce detailed, complex graphics with vibrant colours and gradients.

-

Variety of Textures & Effects

Variety of Textures & EffectsIt also lets you augment your design with different effects like fluorescent, glitter, metallic or velvet.

-

Affordable & Efficient

Affordable & EfficientNo set-up charges makes heat transfer printing particularly useful for smaller orders, especially for more complex designs.

-

Versatile & Highly Durable

Versatile & Highly DurableIt can be used on virtually any fabric, and can withstand frequent washing and wearing to provide lasting results.

Key Advantages Of Transfer Printing (in detail):

The relative simplicity of heat transfer printing enables you to create almost any design, just as you’d be able to by printing from an everyday home or office printer. This means it can create bold, vibrant and complex full-colour designs in a huge range of shades and gradients, with no loss of detail between the transfer paper and the garment.

What’s more, with heat transfer printing you can choose between a variety of effects and textures, from fluorescent tones to metallics, and even velvet. In fact, certain effects are exclusively available with this technique.

Its affordability makes it widely accessible to businesses of any size, including startups. There are no setup charges, so it’s especially cost-effective for smaller orders of more complex designs, and it’s quick and convenient too. It has very short lead times, and theoretically the printing can be done on the same day, which effectively lowers storage costs.

Vinyl transfer printing in particular is also one of the most widely-preferred methods of creating customised sportswear, as it’s a highly durable plastic that can withstand frequent washing and wearing, without impacting the design. That, combined with the cost-effectiveness of transfer printing in small orders, means that it’s perfect for sports team kits.

What Garments Can Transfer Printing Be Used For?

Transfer printing can be used on almost any fabric, including cotton and polyester, lycra sportswear, as well as jackets and other waterproof garments. Its accessibility and cost-effectiveness in small orders means a popular option for small retailers looking to establish their own line of branded clothing for sale to the public, or for internal use, and sports teams can make excellent use of vinyl printed garments due to their longevity and durability.

-

-

-

Coats and Jackets

Keep off grim weather with personalised coats, jackets and workwear.

Explore Range -