Services

We offer a number of specialist print and embroidery services here at City Workwear, all delivered by our very own skilled in-house staff. We’re very passionate about keeping all of our services under one roof, as it enables us to maintain total control over every aspect of each process, allowing us to guarantee products that meet our own high standards of quality, longevity and reliability. No matter what type of personalised workwear you’ve got in mind, you can have total peace of mind that you’ll only ever get the very best when you choose us here at City Workwear.

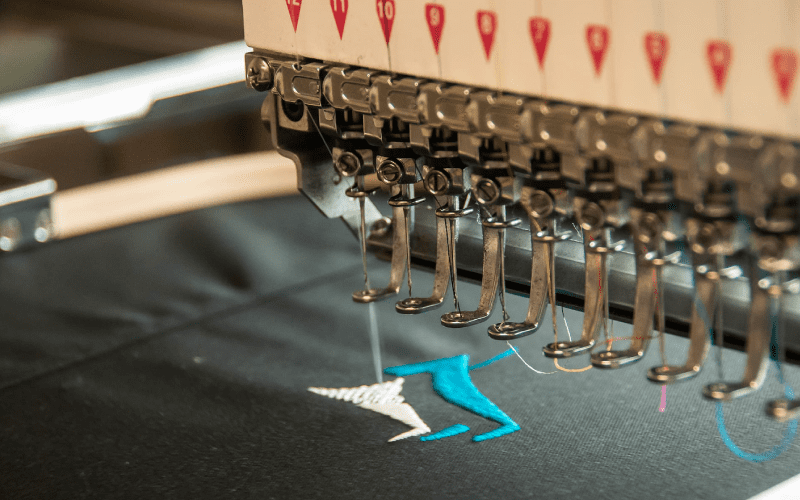

Embroidery

Embroidery is the process of stitching a design directly onto a piece of clothing, producing high-quality, texturised and reliably hard-wearing results. That appearance and durability, combined with its ability to be used with almost any kind of clothing, makes it the preferred choice for countless types of businesses and organisations

Find Out More

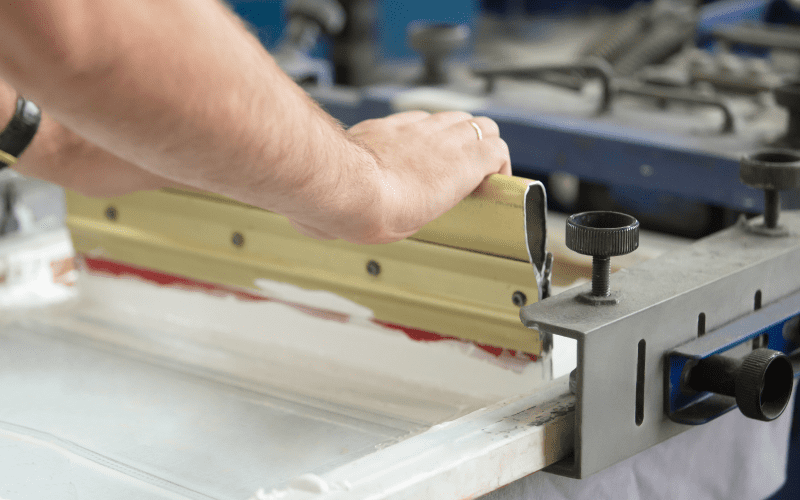

Screen Print

With screen printing, multi-coloured inks are applied to your garment through the use of mesh screens. It’s a great way to create detailed designs or hand-drawn illustrations with bright and vibrant colours - even something as complex as a photograph - and it’s a cost-effective option for bulk purchases or workwear or large-scale product runs of 20 garments or more.

Find Out More

Digital Printing

Sometimes referred to as Direct to Garment printing, digital printing applies the design directly onto the garment, rather than doing so in layers like screen printing, or via a heat transfer sheet like transfer printing. That makes it a brilliant choice for particular intricate or complex designs, or those that incorporate a wide spectrum of colours.

Find Out More

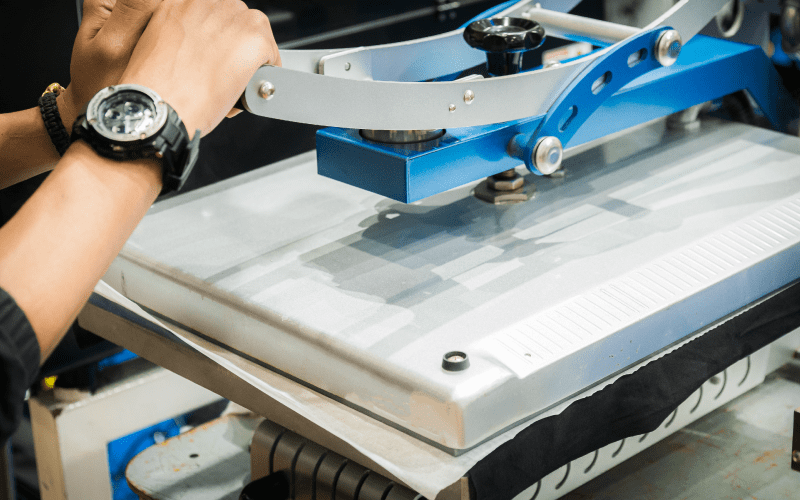

Transfer Printing

Transfer printing is a catch-all term which encompasses a small number of specific techniques that rely on heat to transfer an image from surface to surface. Heat transfer printing uses a transfer sheet to convey the design onto the garment, and it’s an excellent choice for printing detailed, vibrant full-colour designs. Vinyl transfer printing works in much the same way, in which we use a heat press to heat-seal a cut-out sheet of vinyl into the fibres of your garment.

Find Out More